On April 17 2005, the Millstone nuclear generating plant in Connecticut shut down when a circuit board monitoring a steam pressure line short-circuited. In 2006, a huge batch of Swatch watches, made by the eponymous Swiss company, were recalled at an estimated cost of $1bn (£500m). In both cases, "tin whiskers" - microscopic growths of the metal from soldering points on a circuit board - were blamed for causing the problems.

It's not the first time these mysterious growths have been blamed for electronics failures. In 1998 the Galaxy IV communications satellite sputtered out after just five years; engineers diagnosed its failure as due to "whiskers".

The US military blamed them for malfunctioning F-15 radar systems and misguided Phoenix and Patriot missiles. In 1986, the US Food and Drug Administration recalled a number of pacemakers because of these same whiskers. In fact, they've been known about since the 1940s, and happen with cadmium and zinc, too: during the second world war, similar whiskers would short the cadmium tuning capacitors in aircraft radios. A decade later, tin-based relays in AT&T telephone switching centres were found to cause shorts.

Pushing tin

The solution to "whiskering"? Mix lead into the solder, as was done from the 1950s. Colin Hughes, a physicist who worked on the first British nuclear bomb, told me that the whiskering problem never came up during his career.

But now the lead is gone, by legal mandate, and whiskers are back - causing potential problems for us all.

Since 2006, lead has been banned from solder in the European Union under the 2003 Reduction of Hazardous Substance (RoHS) directive, which gave manufacturers three years to phase out lead.

The logic seemed reasonable. Removing lead from petrol (where it was used to prevent engine mistiming) brought clear environmental and health benefits, taking a harmful chemical that can affect intelligence out of the atmosphere. Removing lead from solder, the 37% lead, 63% tin alloy used to join metal objects in everything from plumbing to circuit boards, was an obvious next step to prevent it leaching into ground water from dumped items in landfills.

Meanwhile, the US and Japan have also been moving to lead-free solders. It's a huge shift; the US Environmental Protection Agency (EPA) estimates that 80m kilograms of lead solder was used worldwide in 2002. Environmental groups have applauded the move. "In the US we've been surviving without lead solder for many years," says Rick Hind, legislative director of Greenpeace's toxics campaign. "With less exposure to lead we will all benefit by being smarter and making safer and more durable products." (The US has not made lead-free solder obligatory, but does offer tax benefits for doing so.)

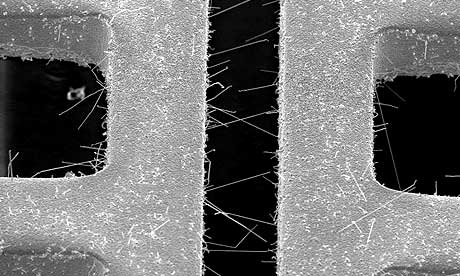

But without lead to tame it, tin behaves oddly on circuit boards. Left alone, tin plating, like cadmium and zinc, spontaneously generates microscopic shreds of metal - about one to five microns in diameter, or less than one-tenth as wide as a human hair - which push up from the base. If they grow far enough to touch another current-carrying location, they'll cause a short that can wreck the equipment while leaving barely any trace.

The cause is becoming clearer. "I believe the mechanism of whisker formation is now understood: it is due to compressive stress - caused by, say, diffusion of copper into the tin - being built up in the tin layer which breaks through the tin oxide barrier layer [to the air]," says Steve Jones of Circatex, in South Shields. Critics cite reports that solder substitutes - pure tin, tin-zinc, tin-silver-copper - simply cannot match the lead mixture for reliability, coverage ("wetting" terminals), and cost (silver is especially pricey). Therefore, the US military, Nasa and medical and high-level research equipment are exempt from what authorities view as untrustworthy commercial components.

"I still use lead-tin solder - it works better," says John Ketterson, a solid state physicist at Northwestern University in Illinois. He notes the tradeoffs of "cost, materials, strength of the solder and all that" during this mandated changeover, and that manufacturers "have to get an experience base" with new processes.

Double standards

This means the unwitting consumer bears the cost of the experimental burden. "So Nasa does not want the economic risk of having the Hubble [Space Telescope] go down. But if one personal computer in a thousand goes down because of the whiskers, no one is going to do anything much about it," says Ketterson.

One in a thousand may be a generously low estimate. Besides whiskering, lead-free solder is more brittle. Substitute solders also may be applied too thinly or with too little heat - or, for that matter, with too much heat (lead substitutes have higher melting points), stressing the circuit board laminate.

The question is, are the products we are using now being affected by tin whiskers? When your computer stops working, could that be the cause? Certainly, some in the computer industry know about it: representatives from Sun Microsystems and IBM were among those presenting at a tin whisker workshop in 2006 ; a second is due later this month.

Using a matt finish, removing contaminants from the solder and surfaces, and reducing mechanical stress on the components being soldered all mitigate the growth of whiskers. But Bob Willis, an opponent of the EU directive and technical director for the SMART (Surface Mount and Related Technology) Group in the UK, says that so far there is "no definite solution to the problem".

More than 80% of all electronic components are made in Asia but specifications are imposed by the brand-name company. I rang eight manufacturers to enquire about encounters with whiskers and related problems. Only one tech support person - and no spokesperson - knew anything about it. Yet Google "tin whiskers" and you get 40,000 hits.

Apple was the only manufacturer to respond, stating that the company "has been using lead-free solders since 2004 without issue". Perhaps manufacturers haven't developed an "experience base", or perhaps it isn't registering as a problem. Many customers will probably chalk failed devices off to their own isolated tough luck, when the cause might really have been microscopic whiskers inside their machines.

Lessons learned

Overall, was it sensible to go lead-free? "I would say no," says Willis. Earlier obsolescence means more discarded devices. Critics argue that substitutes are more toxic and energy-wasteful than the lead they replace - and that lead doesn't leach from circuit boards, because it doesn't migrate as lead in paint or petrol does.

The National Electronics Manufacturing Centre for Excellence, sponsored by the US Navy, did find that modifying the temperatures at which soldered items are bathed and stored diminished whiskering, but nevertheless recommends the "use of lead in conflict with future industrial practice." And Swatch, after its expensive recall, won a permanent exemption from the RoHS directive for its exports to the European Union.

Perhaps a reliable lead-free process will be conjured up soon - though experts doubt it. Companies such as IBM and National Instruments say they are now achieving RoHS compliant techniques even for exempt products. But this debate among professionals looks like it needs to come out in the open. So far, the last source to count on for information about this looming problem is the manufacturers.

Tin whiskers: coming to a PC near you?

· They can grow at ambient temperature and humidity, or in vacuum

· They can grow in steady or varying temperatures (though the latter may encourage growth)

· Whiskers' tips are atom-sharp. They will push through any coating, given time

· They are a prevalent cause, only now being identified, of many past equipment failures

· One whisker can carry about 30mA - more than enough to cause havoc in digital circuits

· Silver-tin-copper ("SAC") solder slows but doesn't stop whisker growth

· SAC solder has more environmental impact than the lead-tin version

· Older 37%-63% lead-tin solder mix merely deforms, reducing stress and hence minimising whiskering

· Whiskers can grow indefinitely

Source: Howard Johnson, Signal Consulting