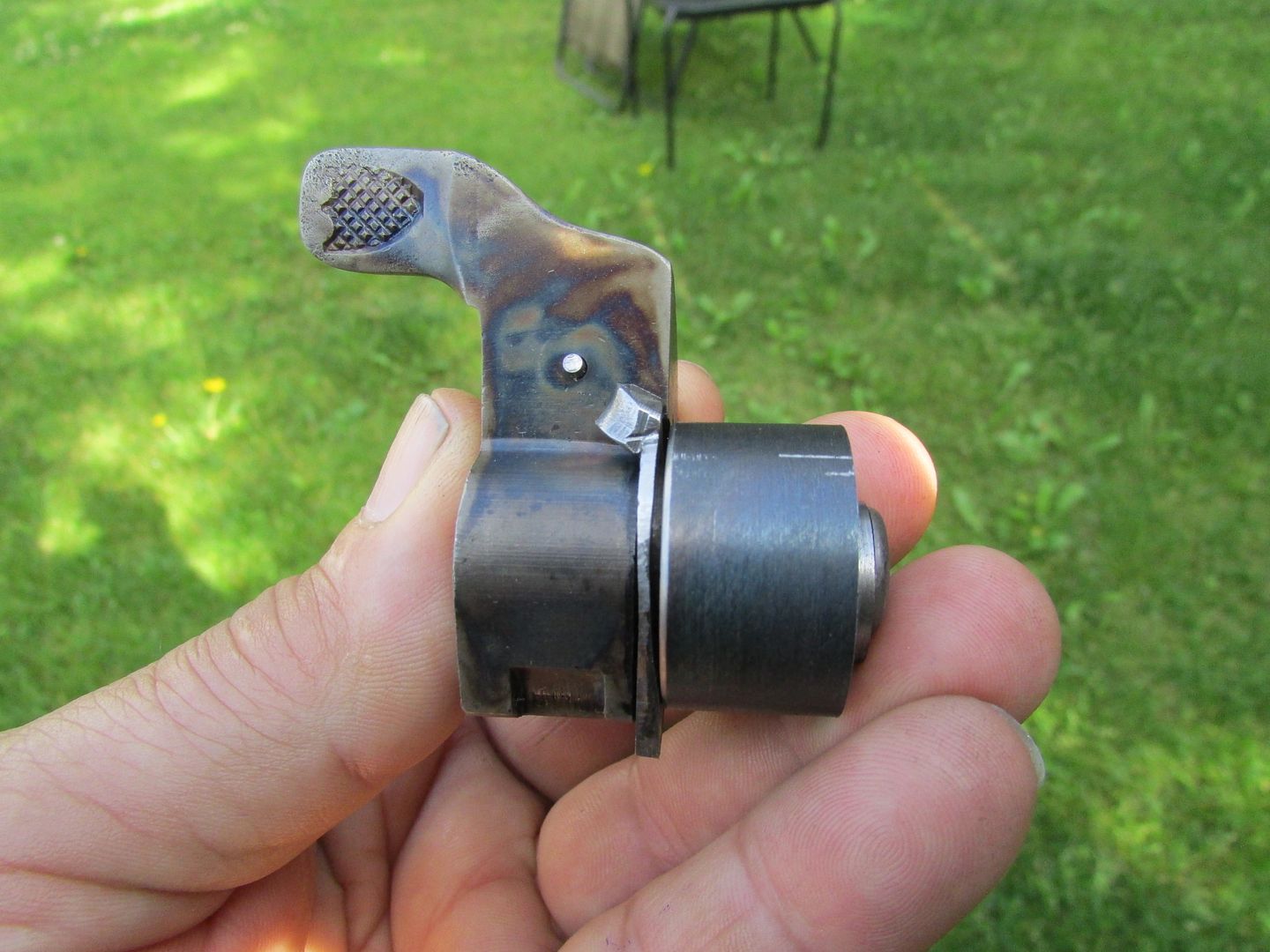

Laid out and turned the eccentric on the mock up block to fit the new extractor tonight. It could be done with an old barrel root if I had one but the action came to me barreless. This will allow a closer fit anyway as I can swing it up to the breach face and scribe around making a very close fit in the barrel and I will have it to fit any more I come across in the future.

After getting the pin hole cut and snugly fit in the mock up block I turned a pin to the diameter of the extractor hole and cut a center in it. I then parted it off , dressed it up and used it to locate the center of the eccentric by gluing it in the correct position after laying it out on the mock block face.

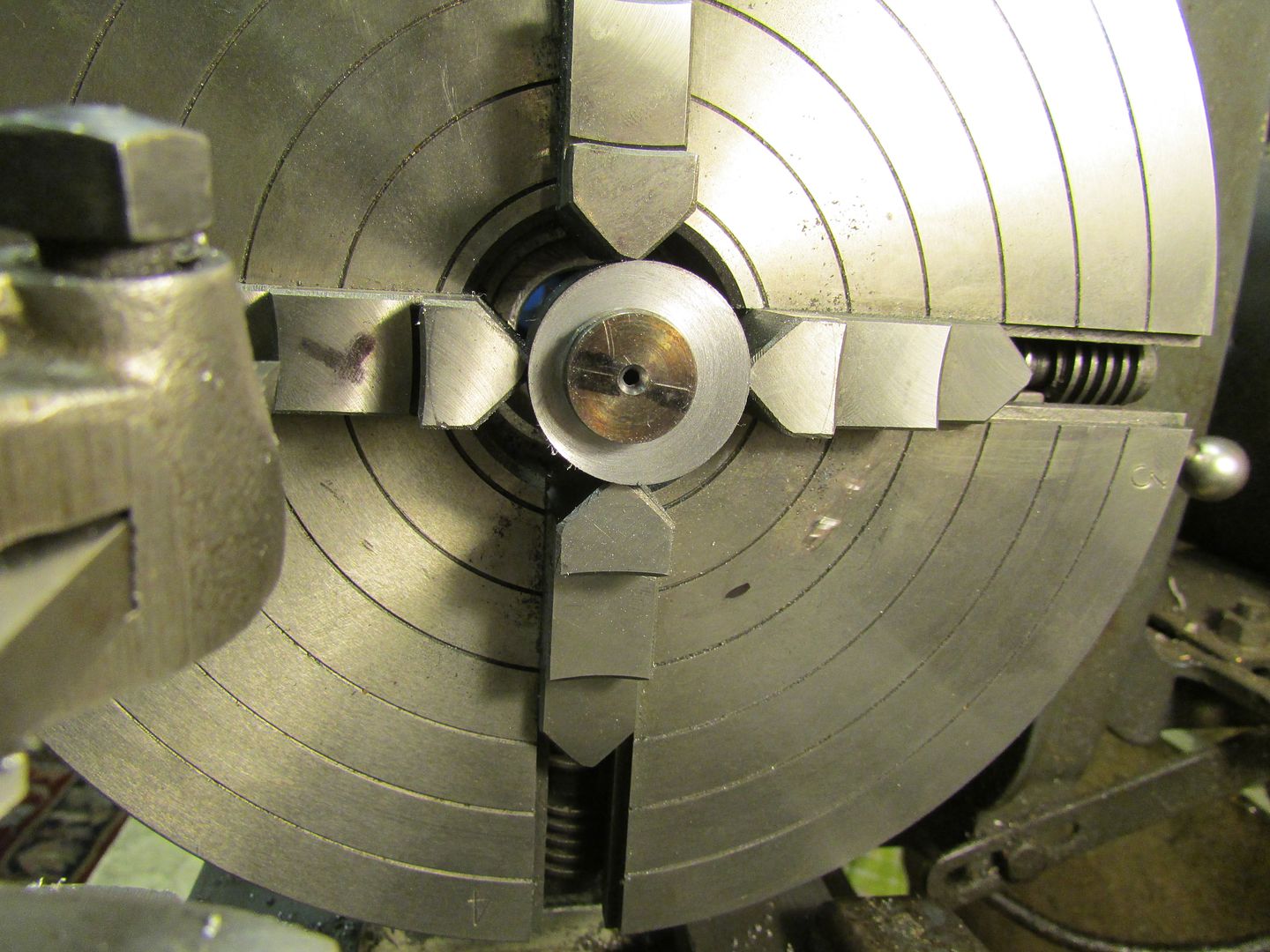

I then used a wiggler in the tail stock drill chuck to center it in the lathe four jaw chuck. Now it was set up to turn the eccentric the depth of the extractor thickness.

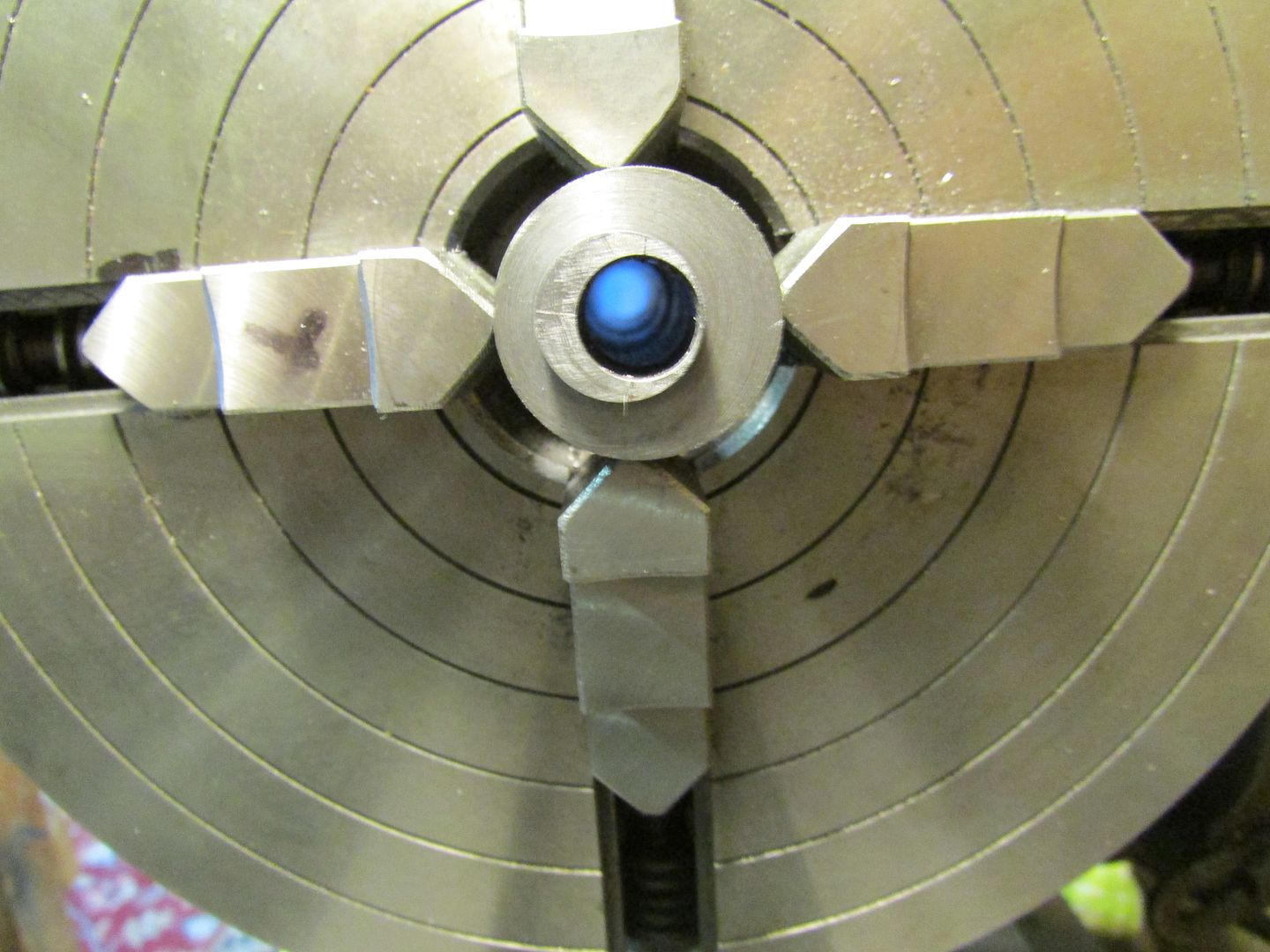

Turning completed and the center disk removed.

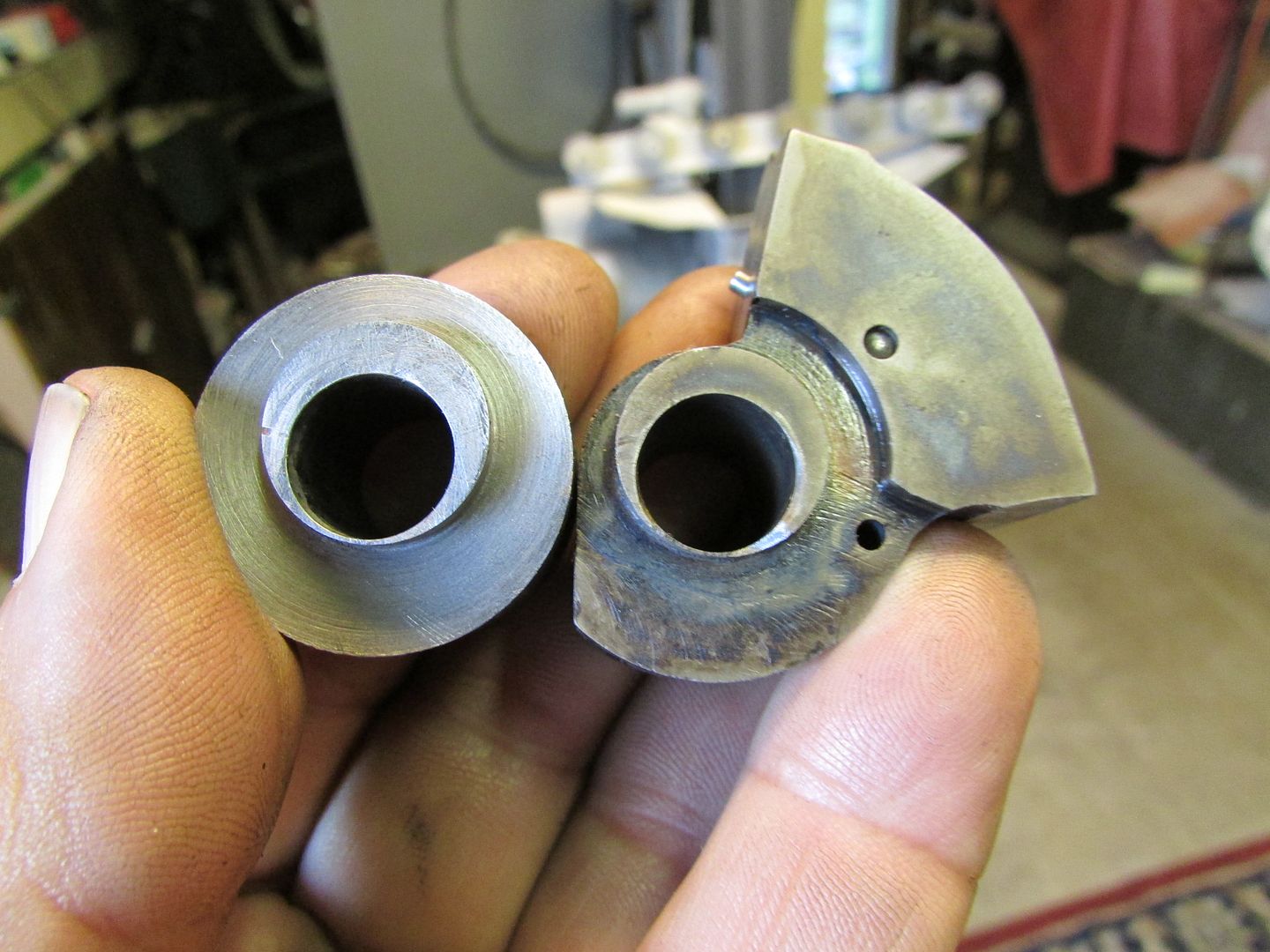

Here are the blocks compared. I have to mill away the front section of the mock block for clearance against the barrel root so it can swing up and cam the extractor into correct position just as the action block does.

Here the two blocks are pinned together so you can see how it works. The top half of the mock block is gone so I can perfectly fit the ring ejector to the barrel face as it swings into correct position on it's eccentric seat.

I will have to locate top dead center and drill a stop pin to properly locate the extractor claw on the barrel face. It came out within .002 of the same height as the action block so was pleased with the accuracy. Mike D.